Choosing The Right Bandsaw Blade

Bandsaw blades come in a variety of materials, tooth designs, widths, and configurations. When choosing a blade, it mainly comes down to two things: the maximum accommodation capacity and the minimum cut radius. If you are re-sawing or cut-off sawing, use the maximum blade width of your bandsaw as this will keep the cuts straight and you will get a good belt feed rate without breaking the blade.

The thickness of the blade has to be properly chosen as well. If the proper thickness is not used, it can lead to continual flexing, and heating and cooling causes the metal to fatigue and ultimately fail. Choosing the proper thickness of the blade depends on the diameter of the wheels and the work you are doing. Thicker blades can withstand more strain from straight cuts but are more susceptible to break from bending and twisting action. Thinner blades perform better under lighter loads.

How Many Teeth Does Your Blade Need?

In general, you want to try to keep at least three teeth in the material when cutting, this allows for greater stability of the blade and more precise and accurate cuts. Blades with more teeth per inch (TPI) cut slower and more smoothly, and blades with fewer teeth cut faster and with a slightly rougher finish.

Coarse tooth blades with 2 or 3 TPI should be used for re-sawing and cutting thicker materials. 4 TPI blades are used for coarse, fast cutting, generally 3/4” wood material. 14 TPI blades are used for slower, smoother cuts, and 6-8 TPI blades are good for general-purpose cutting. For materials thinner than 1/4” a finer blade around 18-32 TPI should be used.

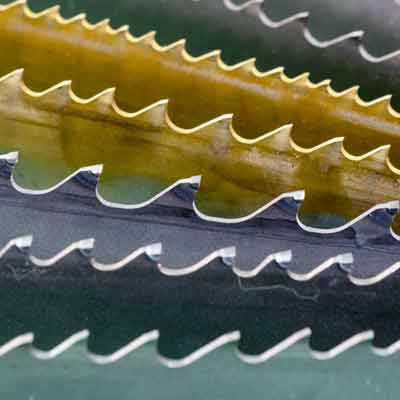

Blade Tooth Sets and Style

Tooth styles for your bandsaw blade have three basic categories: regular, hook, and skip.

Regular tooth blades have their teeth spaced proportionally and are ideal for cutting fine-finish thin materials, contour sawing, and general-purpose cutting.

Hook took bandsaw blades have generally larger teeth and a +10-degree rake angle. This angle along with the larger teeth help the blade to feed into the material more aggressively, also resulting in faster cutting rates. Hook blades are common use when making longer cuts in thicker wood, hardwood, metal, or plastic.

Skip tooth blades have their teeth spaced widely and have a 0-degree rake angle as to disallow clogging when cutting soft wood, plastics, and non-ferrous metals.

For joinery and cutting curves, a variable pitch blade provides a fast cut with a smooth finish with its alternating sets of different sized teeth.

To see a blade’s set, look down on the teeth.

A raker tooth set has a tooth to one side, followed by a tooth going to the other side, and a straight tooth, called a raker.

A tooth set without the straight tooth is called an alternate tooth set. The pattern for this kind of set has a tooth going to the left, followed by a tooth to the right, continued with no straight tooth. There is a double alternate plus raker set has a straight raker tooth that comes after two side-teeth combinations.

Choosing The Right Blade Set

Choosing the appropriate blade set will provide a good balance between the amount of sawdust produced and the amount of air in the space between the body of the saw blade and the material that is being cut.

Too high of a set results in not enough sawdust, too much air, and can leave tooth marks on the material you are cutting.

Too low of a set will restrict airflow and will limit the ability of the blade to pull sawdust away from the cut. This will create hot, packed sawdust that leads to shortcutting times and can cause premature breakage of the blade.

Bands that are excessively under set can result in a non-straight cut.

Keep Your Surface Feet Per Minute (SFM) In Mind

Setting the proper speed for the material you are cutting is important and you need to know the SFM for the various settings of your bandsaw. Your owner’s manual will hold the SFM settings, but if you don’t have the specs from the manufacturer, use this formula:

SFM = Drive Wheel RPM x Drive Wheel Diameter x 0.262

Choosing The Right Blade Size

Choosing the proper blade size is essential to your bandsaw’s performance. If you have a manual and markings on your machine, follow those, otherwise, you can follow these steps to find the proper blade length:

Set pulleys or wheels in working position.

Measure the distance between the center hub on the upper and lower band wheels. (C)

Measure the radius of the upper and lower drive wheels. (R1 & R2)

Calculate the blade length:

Blade Length – (R1 x 3.1416) + (R2 x 3.1416) + (2 x C)

OUR SERVICE AREA

We provide industrial supplies and vendor-managed inventory to customers all over the Atlanta Metropolitan area in Georgia. This includes Alpharetta, Auburn, Bogart, Braselton, Buford, Commerce, Cumming, Dacula, Hoschton, Jefferson, Monroe, Statham, and Winder. If your looking for industrials supplies from an affordable and reputable company GTA is here for you!

Our goal is to be more than your main industrial supply company. We want to partner with our customers to help increase your business efficiency and production.

Our Location

738 West Winder Industrial Pkwy

Suite A

Winder, Ga. 30680

Phone: 678 288-5881